Have A Info About How To Build A Vacuum Press

Large vacuum formers are super awesome, but can't just be purchased like other equipment.

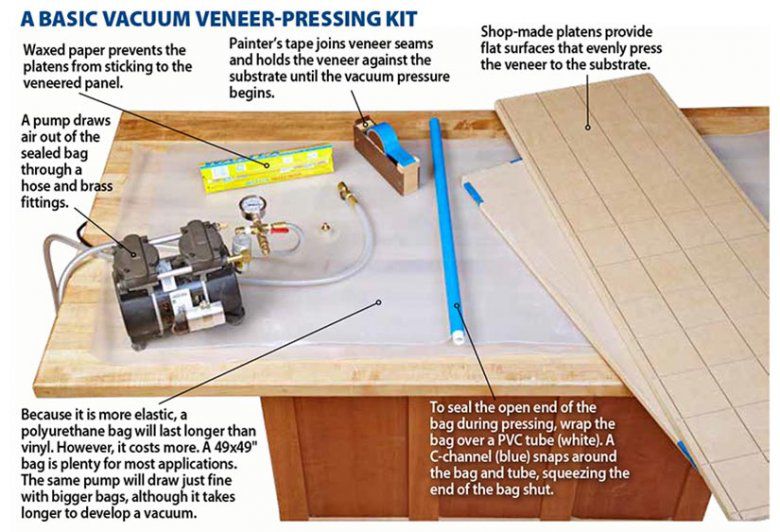

How to build a vacuum press. I used boat canopy window vinyl for bag material, and some brass fit. You can build almost any kind of vacuum press using the parts found below or jump right into veneering with our line of excel™ vacuum press kits. A vacuum press is a very powerful tool that is capable of producing over 1700 pounds per square foot of pressure at full capacity.

It's very affordable compared to the big name vacuum presses which can cost $700. There are instructions for building a system that is. For this reason i decided to build one.

Greetings,after selling the last of our inventory, thermapress permanently ceased operations on march 30th, 2021. Our website remained active and provided t. We also offer a full line of vacuum bags.

How to make a vacuum press for kydex silicon rubber sheet 1x3” board 1x2” board plywood pegboard screws (you can choose drywall) ¼” bolts, washers, and nuts 11/4” hole saw. Assuming you are at about 800 ft. A thin layer of fine mesh cloth creates a uniform finished look as the epoxy cures in the vacuum bag.

Commercially available vacuum presses capable of large scale work can be quite pricey. To make a holster the kydex will be heated to 350 degrees and then the gun mold will be placed on the vacuum table and the kydex placed over it. The lid is clamped shut and.

The heated kydex is wrapped around whatever it will sheathe, and. The average builder can have the system completed in a few hours. It can’t possibly be more than about 14.7 psi (29.9 inches of mercury), as that’s the air pressure at sea level.